May 4, 2021

Name: Mike Dougherty

E-mail: mikedougherty63@yahoo.com

Shop: 56 shop

I was a second year apprentice when I reported to Al Stranahan At the marine

railway.What a classy guy.He gave me a tour of USS Trutta explaining how we were

gonna "save the Trutta"and give her to the Turks .Now I realize that he was

teaching me How to orient the new guy.I became friends with a young Turkish

sailor and his chief started hitting him when he caught us shooting the

breeze.Since I was still in my street gang phase I attacked the chief.Al got me

out of that trouble.I learned that the main job of the foreman was to protect

his men.I sure miss the Yard!

![]()

February 4, 2021

Name: Dennis J Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911

Another Obituary. Sorry for all the bad news.

Martin (Marty) Sheeron Jr

PNSY Boilermaker Production Superintendent

Martin J. "Marty" Sheeron passed away peacefully on January 30, 2021 from

Mesothelioma. Marty started his long career at the Shipyard in July of 1968. In

July, 1969, he made the decision to enlist in the United States Army. After

serving in Vietnam and Germany, he returned home to the Shipyard in March, 1972

to resume his Boilermaker Apprenticeship. He graduated from the Apprenticeship

in December 1975.

Marty was promoted to Boilermaker Foreman in 1979, then to Boilermaker General

Foreman in 1983, and finally in 1989, to Boilermaker Production Superintendent.

His family never questioned the long hours the Shipyard demanded of Marty. He

believed the people he worked with at the Shipyard were the best of the best.

In 1995, Marty left the Shipyard and took a position with the Commonwealth of

Pennsylvania as a Boiler Inspector Supervisor. He worked for the Commonwealth

until his retirement in January 2016. Marty always said his job as Boilermaker,

Boilermaker Foreman, and Boilermaker General Foreman were great jobs, but his

job as Boilermaker Production Superintendent was his hardest but most rewarding

job of them all. He considered it the best job he ever had.

Marty leaves behind his beloved wife Diane J. Palmer Sheeron, who kept the

family strong and together when he was away at the Shipyard. He is also survived

by his children; Marty Sheeron (Philadelphia Detective) and his wife Bernadette,

Kevin Sheeron (420 Steamfitter) and his wife Erin, and Carrie Bickel and her

husband Patrick (Project Manager/Retired Army Officer), as well as 8 wonderful

and loving grandchildren.

Relatives and friends are invited to Marty's Funeral Mass on Thursday, February

11, 2021 at 11:00 AM at St. Cecilia Catholic Church, 525 Rhawn Street,

Philadelphia, PA 19111. His interment at Washington Crossing National Cemetery,

Newtown, PA will follow at 1:00 PM with full military honors.

![]()

February 3, 2021

Name: Dennis J Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911

I was asked to share this with the Ex-Yardbirds:

Casper "Pat" on January 31, 2021 of Country Club Estates in Deptford. Age 63.

Loving husband of Joyce M. (Nee Parks) for forty years. Son of the late John

Casper and Naomi (nee Ciriglo). Beloved father of Jennifer Casper of Mantua,

Katherine Vasta (Mario) of Deptford and Patrick J. Casper (Casey) of Mantua.

Brother of Steve Casper (Natalie) of Deptford and the late John Casper. Devoted

grandfather of Braxton and Iyla. Also survived by many nieces and nephews. Pat

was an inspector for NJDOT and formerly worked at Philadelphia Navy Yard Pipe

Insulators 57 Shop. He was an avid Philadelphia sports fan, enjoyed smoking

cigars and loved being involved in his children's sports. Most of all, Pat loved

spending time with his family. Relatives and friends are invited to a viewing on

Friday, February 5, 2021 from 7pm to 9pm and Saturday, February 6, 2021 from

9:30am to 10:15am in The Chapel at BOUCHER FUNERAL HOME, 1757 Delsea Dr.,

Deptford, NJ 08096. A Mass of Christian Burial 11am at Holy Angels Parish at St.

Patrick's RC Church, 86 Cooper St., Woodbury, NJ 08096. Interment Wenonah

Cemetery, Wenonah. For directions, to sign online guest book and to view Pat's

Video Tribute visit

www.boucherfuneralhome.com. MASKS MUST BE WORN COVERING NOSE AND MOUTH

ENTERING THE FUNERAL HOME AND THE CHURCH. Boucher Funeral Home 1757 Delsea Dr.

Deptford, NJ 08096 856-464-1097

![]()

January 21, 2021

Name: William j Domzalski

E-mail: rigger072@yahoo.com

Shop: 972

sad to report the death of Carl "SKI" Kurzawski X72 shop Rigger..If you worked

the SLEP program on any Carrier ,and needed some fork truck service you knew

"SKI"..R.I.P.

![]()

January 16, 2021

Name: Ron Miller

E-mail: ronfish2002@yahoo.com

Shop: X31

Three of my coworkers at the US MInt who once worked at the Yard have recently

passed away: Charlie Burke - 31 Shop; Bruce Dickerson and Bill Eggers - both 38

Shop.

![]()

January 14, 2021

Name: Clifford A Nash

E-mail: pnsycliff@aol.com

Shop: 06

Stephen F. Weber, Sr.

Stratford - age 78, passed away on January 4, 2021. Survived by

his wife of 55 years, Dorothea "Dot" (nee VanDenEnde); children Rita (Lucky)

Hawkins, Stacey, Stephen (Christina), Elizabeth (Francis) Dubinink, and Franny

(Tracy) Walsh; grandchildren Samantha, Evan, Sarah, Sophia, Alexis, Trevor, and

Quinton; sister-in-law Theresa Weber; brother Laurence Weber; and brother-in-law

Leo Canniff. He is predeceased by his siblings Herbert Weber and Rosemary

(Weber) Canniff, and sister-in-law Barbara Weber.

Stephen proudly served in the US Navy. After the service, he began his career as

a general foreman electrician at the Philadelphia Naval Shipyard. He enjoyed

participating in the Naval Yard bowling league, traveling and cruising with his

family, rooting for the Boston Red Sox, and listening to Neil Diamond.

![]()

January 12, 2021

Name: Joe DeKraft

E-mail: joedek@verizon.net

Shop: X17;C/265

John, I started working @ PNSY in January of 1967 six months after I got out oh

high school. Of course everyone always remembers the USS New Jersey but not

everyone thinks about the submarines as much. As I was around The Navy Yard back

then I remember two particular submarines from back then and used during Open

House tours back then and one was the USS Bang. Here are two Wikipedia links for

both of those submarines. The USS Bang was sold to Spain and was eventually

scrapped in 1983.

https://en.wikipedia.org/wiki/USS_Bang

The second submarine I remember was the USS Becuna and is still around today and

is docked at Penns Landing right next to the USS Olympia in Philadelphia.

https://en.wikipedia.org/wiki/USS_Becuna

![]()

January 10, 2021

Name: John Urbanski

E-mail: Jcurbanski@yahoo.com

Shop: Yard visitor

About 1965,my Cub Scout group visited the Naval Yard. We toured the New Jersey

which was mothballed at the time, and we also toured a USN submarine that was

there. If memory serves me, I remember it being a WWII fleet boat. Can anyone ID

her for me? Thanks much.

![]()

January 7, 2021

Name: Clifford A Nash

E-mail: pnsycliff@aol.com

Shop: 06

My heartfelt condolences for the family of Jim Merkins. We started together as

Toolmaker apprentices in 1969. RIP Jim

![]()

January 4, 2021

Name: Jack Hofbauer

E-mail: johnhofbauer@comcast.net

Shop: 06 toolmakers/Code 380

I was so sorry to hear of the passing of Jim Merkins. I worked with Jim and for

Jim for many years as a toolmaker. Jim was one of the best guys to work with and

"the best" supervisor I've ever worked for. He never forgot where he came from

and never let the power go to his head. Jim was well liked and respected by

everyone who knew him and he was always a pleasure to be around and talk to. We

worked together, played softball together, went fishing together, and enjoyed

many lunches at the Navy Yard parade ground put out by the sailors. Jim always

stood up for his workers and was a real team player. You're another good man

gone too soon and you'll be missed by everyone. RIP my friend!

![]()

January 2, 2021

Name: Tom ( Rock) DeMarco

E-mail: tomdemarco1@gmail.com

Shop: 72R

James J. "Jim" Merkins, Sr., 75, of Aston PA, passed away peacefully on Dec. 30,

2020, surrounded by family.

Raised in Fernwood, PA, Jim graduated from St. Cyril's School in East Lansdowne

and Upper Darby High School (Class of '62). He was an accomplished student and

athlete, excelling at all sports, especially wrestling.

Jim served his country enlisting in the United States Army training at Fort

Sill, Oklahoma, and serving tours in Germany and Vietnam, earning the rank of

Platoon Sergeant. Jim subsequently worked at the Philadelphia Naval Shipyard for

40 years as a toolmaker, retiring as General Foreman of the Naval Foundry and

Propeller Center. After retirement, Jim worked for Penn Delco School District as

a beloved bus driver.

Jim married his high school sweetheart Lorrie in 1969. They had a beautiful

marriage of 51 years. Lorrie was the love of his life and by his side for the

last several weeks as he bravely battled Covid-19. Jim's greatest love was his

family and in addition to his devoted wife, was survived by his four children:

Lorian Ruggeri (Chris), Janna Palaia (Jason), Jim Merkins (Suzy), Taryn Kraus

(Dennis) and 8 grandchildren, Annie, Christopher, James III, Alexander, Lauren,

Morgan, Gregory, and Drew, as well as many cousins, nieces and nephews. Jim was

the son of the late Robert and Eugenie Merkins and preceded in death by his

brothers Robert, George and Bernard, sisters Norma and

Suzanne, and son-in-law Lt. Gregory Fulco, USN.

Jim brought his love of sports to the youth of Aston committing many years to

coaching basketball, soccer and baseball. Jim was the Commissioner of the Aston

AA Girls Basketball League and earned a spot in the Aston Sports Hall of Fame

for his dedication. Jim never missed his children's sporting events and enjoyed

taking them and his grandchildren to Phillies games.

In recent years, Jim spent his summers at the shore with family in Wildwood

Crest. He could often be found dancing with Lorrie or holding a microphone

singing a song for all to enjoy. Jim had a beautiful voice that many will miss,

especially on July 4th when he would sing "Proud to be an American" at LaCosta

in Sea Isle.

All who knew Jim would describe him as a devoted family man and a true

gentleman.

He will be missed by all who have had the honor of meeting him.

Visitation: Relatives and friends are invited to his viewing Wednesday evening,

6-8:00pm, D'Anjolell Stigale Memorial Home, 3260 Concord Rd., Aston, and

Thursday, 9:30-10:45am, St. Joseph Church, 3255 Concord Rd., Aston. A Funeral

Mass will follow visitation on Thursday, 11am. Interment will be in SS Peter &

Paul Cemetery.

![]()

January 1, 2021

Name: Tom Maiorano

E-mail: tmaiorano1@verizon.net

Shop: 38 Shop

Happy New Year to all at PNSY. Hope and pray this year will be better than the

last one.

![]()

December 28, 2020

Name: Julio Casiano

E-mail: Jullio@Philly-Yardbird.com

Shop: 26

Sad news about Sean Murray. He was in the first apprentice class I had when I went to the welding school. I remember he was a dedicated hard worker.

![]()

December 28, 2020

Name: John Stangler

E-mail: jcstangler@aol.com

Shop: 26

Share:

Sean P. Murray, of Philadelphia, passed away on November 1st 2020 at the age of

56. Sean was the loving son of the late John P. and Susan P. (nee Brennan) and

brother to the late Maureen Sciandra. Sean will be greatly missed by his sister

Susan Hill (Robert), and his brothers; Frank Murray (Judy) and Dan Murray. Sean

leaves behind a loving legacy in his many nieces and nephews; Christie Cochrane

(John), Erin Rodstein (Eric), Jules Hill (Steve), Bridget Murray, Joseph Murray,

Chris Murray, Ryan Murray, Patrick Murray, William Murray, Jocelin Murray, Megan

Sciandra, and Kelly Sciandra, as well as great niece Grace Cochrane and great

nephew Jack Souder.

Sean was an avid Philadelphia Phillies and Flyers fan, following his teams

throughout each season was a great love of his. Sean will be remembered for his

hard work as a welder with the Navy Yard and his love for his family. When Sean

was not working, he enjoyed spending his time on the water fishing, especially

at the New Jersey shore.

Private family services will be held for Sean. Relatives and friends are invited

to reach out to the Murray, Hill, and Sciandra families to offer words of

support and memories of Sean. In lieu of flowers, donations in Sean's memory to

Philabundance would be greatly appreciated.

https://www.philabundance.org/

![]()

December 20, 2020

Name: Robert Edward Daley

E-mail: hogdale@hotmail.com

Shop: 51

Well, I have asked before with not much luck, but I'll give it another try. I

worked at the yard in the late 70s to the mid 80s and had a boss named Bill

Adair AKA rotten Ralph. I have no idea where that came from.

Anyway, had hoped to make contact with him so maybe I could meet up with him the

next time I come back east. Anyone heard from him ?

Thanks Bob

![]()

December 20, 2020

Name: Dennis J Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911

To all the Yard Birds, and your Families, Merry Christmas and Happy New Year.

November 28, 2020

Name: richard beggs

E-mail: RICH.BEGGS@VERIZON.NET

Shop: 064

Kipling's tribute to an English GI

ITS TOMMY THIS OR TOMMY THAT - OR TOMMY GO AWAY

BUT ITS HELLO TOMMY WHEN THE BAND BEGINS TO PLAY.

Veterans day 2020

![]()

November 11, 2020

Name: lee bidlack

E-mail: fordlightning@etex.net

Shop: 06

Happy Veterans Day, Y'all. Thank you for your service.

![]()

September 15, 2020

Name: Clifford Nash

E-mail: pnsycliff@aol.com

Shop: 06

PNSY closed 25 years ago today. WOW

![]()

August 30, 2020

Name: James L Perkins

E-mail: jimbo09991@netzero.com

Shop: 56

Just saw the obituary for my good friend John Malamon. Appentice classmate,

co-worker, and good friend. R.I.P.

![]()

August 27, 2020

Name: Dennis J Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911

CHARLES (Charlie) Martin 38 Shop Foreman

https://www.allowayfh.com/obituary/charles-martin

U.S. Veteran

On August 23, 2020, age 91, of Cherry Hill, NJ. He was the loving husband of

Margaret (nee Cox) and loving father of Lynn (Joe) Nicklous and Charles W., Jr.

(Valerie). He is also survived by five grandsons; two great grandsons; two great

granddaughters; and one sister Janice Henson. Mr. Martin retired from the United

States Navy and later retired as 38 Shop Foreman at the Philadelphia Naval Ship

Yard. He was a member of the Fleet Reserve and was also a Boy Scout Leader for

Troop #127. Relatives and friends are invited to attend his Funeral Service on

Monday morning at 10:30 AM in the Alloway Funeral Home 315 E. Maple Avenue

Merchantville, NJ. Interment Brig. Gen. Wm. C. Doyle Veterans Cemetery

Arneytown, NJ. There will be a viewing Sunday evening from 6:00-9:00 PM in the

funeral home. In lieu of flowers, donations may be made to a charity of the

donor's choice.

![]()

August 5, 2020

Name: Clifford Nash

E-mail: pnsycliff@aol.com

Shop: 06

Gov Murphy has withheld the NJ Home Stead Rebate and the Senior property freeze

for this year. If this affects you and your family, you can sign apetition at

senatenj.com/petitions/propertytaxrelief/

![]()

August 1, 2020

Name: Roger Nabors

E-mail:

Shop: 99

Last August I was diagnosed with Multiple Myeloma.I received targeted therapy

until Dec. When I recieved a bone marrow tansplant.I was in remission until The

middle of July when I found out that the cancer has come back In my bone marrow.

Although my treatment team does not know what causes this type of cancer I

wonder if it is something I was exposed to at the yard. Anyone else hear of any

ex yardbirds getting this type of cancer? I hope everyone is well.

![]()

July 27, 2020

Name: Tom ( Rocky ) DeMarco

E-mail: tomdemarco1@gmail.com

Shop: 72R

July 27, 2020

If you read the post from today 3 more Yardbirds have passed , my Condolences to

their families !!

Boe Collings x38

Gene Usher x 31

George Tittermary x 56

Keep their names alive !!

Post more info as I see it

![]()

July 27, 2020

Name: richard beggs

E-mail: rich.beggs@verizon.net

Shop: 064

Tom Demarco: Why not share your stories and pictures here. Thats what this web

site was created for.

![]()

July 27, 2020

Name: Tom ( Rocky ) DeMarco

E-mail: tomdemarco1@gmail.com

Shop: 72R

We have a Private Facebook Group for PNSY where we can share pictures, stories

and more . Everyone here is welcome and most are a member already . If you would

like to join us and share your stories just request , there are 3 questions to

answer the first one is the most important, just answer or if you dont and I can

see you were a yardbird on your Facebook page , you are in !!

Thanks ,

Rocky 72R

![]()

July 27, 2020

Name: James Yunker Sr

E-mail: yunkerjf@netzero.net

Shop: 67

Got a ltr from Sherry L. Day (investigator for SLD INVESTIGATIONS).She is trying

to reach anyone who may have worked with former Rigger Edward O'Donnell between

1972 and 1979. Mr. O'Donnell passed away as a result of asbestos-related

disease. Anyone with any info please contact her at (734) 878-5236 or

sherry@SLDinvestigations.com

She said she got my name through Ed's wife. Unfortunately I cannot recall him on

any of my ships. Any info will be appreciated by Sherry.

Jim Yunker x67

![]()

July 11, 2020

Name: Cliff Nash

E-mail: pnsycliff@aol.com

Shop: 06

Anyone interested in signing a petition to repeal WEP and GPO offsets

We need to coordinate with others to make more noise for repeal of the offsets!

Are you someone who is willing to reach out to other affected retirees in your

own state, in another state, or in your professional group to get them to back

up our efforts to repeal the GPO and WEP? Here is the opportunity to do that!

SSF is working with a nationwide committee from the Alliance for Retired

Americans, retired public workers who are cheated by the offsets. Like our

group, they come from a number of different states and represent different

professions. Working together we can make a greater impact!

Please send us an email to

ssfairness@gmail.com and we will match you up with someone else who wants to

stir up activity for repeal in your state, region or professional group.

Please include the following information:

Name:

Occupation:

Retired or Not retired:

Professional or retiree memberships or other affiliations:

City of residence:

State:

Email:

Phone number (so we can check with you personally before we give out your

information to a prospective partner):

Add your comments, suggestions:

Please send this information to:

ssfairness@gmail.com

As of this writing, the petition to repeal the GPO/WEP has more than 50 thousand

signatures. Thank you for signing and sharing it with your friends and family!

There is a link below so you can send it out again and make sure your friends

and family have supported you by signing on.

https://sign.moveon.org/petitions/elimination-of-the-unfair

(We have no affiliation with MoveOn, but are using their free platform to

collect signatures.)

Copyright 2020 Social Security Fairness, All rights reserved.

![]()

July 4, 2020

Name: Tom Maiorano

E-mail: tmaiorano1@verizon.net

Shop: 38 Shop

Happy Birthday America and a Happy 4th to all my PNSY shipmates.

![]()

June 29, 2020

Name: Tom Maiorano

E-mail: tmaiorano1@verizon.net

Shop: 38 Shop

Just found out Paul Bramley, ex Rigger G. F. passed away the other day. Have no

more info at present time

![]()

June 27, 2020

Name: Dennis J Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911

BALDINI

VITO P. "HOT ROD"

Shop 38

80 years young, on June 23rd, 2020. Survived by his beloved wife Irene (nee

Carroll); his loving children Alessandra, Maria Kelley (Dave), Danielle, and

Vito F. (Amrah); also his 5 cherished grandchildren. Funeral Mass Wed. July 1st,

10:00 AM at Our Lady Of Lourdes Church, 6301 Woodbine Ave, Philadelphia, PA

19151. Inurnment SS. Peter and Paul Cem. Contributions St. Thomas More

Scholarship Fund, P.O. Box 294, Drexel Hill, PA 19026

![]()

June 25, 2020

Name: richard beggs

E-mail: rich.beggs@verizon.net

Shop: 064

A LOT OF PRESSURE

We had an opportunity to use a little physics when we were tasked to provide a

blank (cofferdam) on the pump well intake tunnel in dry dock 4. The caisson was

being sent down river to Sun Ship for overhaul. Work was being done on the gates

that separated the pump well sump of dry dock 4 from dry dock 5. This work had

to continue.Dry dock 4 would be flooded with the caisson gone.

We constructed a cofferdam made of two and a half inch douglas fir planks,

twelve inches wide that formed a six foot diameter blank. Four by six inch

strong backs held the planks together. A rubber gasket was applied to the

perimeter of the cofferdam.

A four by six inch steel angle was bolted to the dock wall that at one time held

a screen to prevent debris from entering the tunnel. This provided a guide and

keeper for our blank. We estimated that the water pressure of about 30PSI ( a

force of almost 6600 pounds) would hold the blank in place.

The dock was flooded and the docking officer, whose idea this was, went down

into the sump after the dock was flooded to check for leaks. He reported that

there were none. The work continued on the gates separating the two sumps. The

docking officer left for his next assignment. I retired.

I got a call about six months later. The contractor working on the gates decided

to cycle the pumps to check his work. Apparently, he nor anyone else knew about

the cofferdam. The added suction plus the pressure of the flooded dry dock 4

blew the cofferdam apart, and partially flooded dry dock 5 where the Kitty Hawk

was docked. The flooding was quickly controlled. NCIS investigated the incident.

The only evidence that NCIS discovered was a letter of commendation the docking

officer had written for the shipwrights involved in the project.

The caisson returned from Sun Ship, was sunk and the dock pumped dry.

As Calvin said to Hobbs in the last comic strip by Bill Watterson on December

31, 1995 "Lets go exploring"

![]()

June 24, 2020

Name: richard beggs

E-mail: rich.beggs@verizon.net

Shop: 064

WE OVERHAUL AN ANTIQUE

Dry dock two's caisson was probably 80 years old when we docked it in dry dock

one for it's overhaul. The hull, like the Titanic, was rivetted together. It was

built before Arc welding was invented. We had to have the welding engineer

determine what type of material the hull was made of, and if welding on it was

possible. The welding engineer and 26 shop met and decided the proper methods

for any welding we had to do on the hull.

The wooden fender system which we were replacing, was attached to the hull with

through bolts. Those below the water line always leaked. The wooden cushion

system that the rubber seal was attached to, was secured with threaded studs set

in tapped holes. The deck was like an old sailing ship. Planks bolted to frames

and caulked with cotton, oakum and pitch.

The welders installed blanks on the hull over the holes from the old fender

system. They installed studs for the new fender system, and for securing the

wooden cushion system. Shipfitters installed a new steel deck to replace the old

wooden one. Non skid was added to the new deck.

This overhaul happened around 1985. I often wondered how it held up. I don't

think the dock was used much after the overhaul,

![]()

June 23, 2020

Name: richard beggs

E-mail: rich.beggs@verizon.net

Shop: 064

LIGHT THEM, IF YOU GOT THEM!

My first experience with navigational lights left a lasting impression on me. 64

shop was required, with an inspector present, to plot the location of all the

navigation lights aboard ship, and to align, if necessary, the shields of the

lights. A certification letter was prepared and signed by the inspector

attesting that the lights met the specifications of International Maritime law.

The ship was required to carry the letter.

It was a routine job carried out before the ship left the yard. I was an

apprentice when it was discovered that the light certification wasn't done. The

ship was at the pier, steaming ready to leave. A team of shipwrights went aboard

and started plotting the location of each light. One light remained. It was the

aircraft warning light atop the stub mast - which was about 20 feet high. The

stub mast (bout 8 inches in diameter) had ladder rungs welded on the sides.

Someone had to climb the stub mast and drop the end of a tape measure to the

deck below. Being the youngest, and allegedly the most agile, I got the job. I

climbed the mast, through the stack gas, and dropped the tape to the shipwright

who recorded the measurement. The letter was signed, the ship sailed and I

promised myself that if I was ever in a position responsible for certifying

navigational lights - it would be done while the mast was staged.

![]()

June 23, 2020

Name: richard beggs

E-mail: rich.beggs@verizon.net

Shop: 064

ADAPTABILITY

It was rare for an apprentice to change trades once his apprenticeship started.

An apprentice welder switched to apprentice Shipwright after two years into the

apprenticeship. He became an exceptional shipwright. We also had an apprentice

machinist, that transferred from the Frankford Arsenal when it closed. He too

adapted well to his new trade.

![]()

June 23, 2020

Name: richard beggs

E-mail: rich.beggs@verizon.net

Shop: 064

A LITTLE HELP FROM YOUR FRIENDS

One of the apprentices hired with our class was a veteran. He didn't request a

kit of tools, that he was entitled to. He seemed to be waiting for news that he

won the Irish Sweepstakes. He was gone in a few weeks. He transferred his

apprenticeship to the National Park Service, which maintained Independence Hall

in Phila.

Who even knew such a position existed? He did - apparently.

![]()

June 22, 2020

Name: richard beggs

E-mail: rich.beggs@verizon.net

Shop: 064

KINETIC ENERGY

The Foremen and General Foremen that I worked with were not physicists but they

developed some theories of their own. During dockings/undockings that I was

involved with, I noticed the amount of attention that the General Foreman paid

to the fwd/aft spring lines. He kept adjusting them until they were taut,

without any slack. He explained his theory that a ship landing on the blocks, in

motion, will resume that motion when it becomes waterborne. He didn't know the

science supporting his theory, but he said he saw it happen many times.

He said he saw ships become afloat and surging in one direction or another

without the influence of wind or current. He said, he thought that there was

energy stored in the blocks when the ship landed, and that energy was released

when the ship became afloat.

I followed his example of removing any slack in any of the controlling lines

prior to flooding the dock to refloat the ship. I never took the chance to see

if his theory was valid.

During one undocking of a destroyer in dry dock 2 (I was an observer) little

attention seemed to be paid to fwd/aft spring lines. They had slack in them.

There wa no wind, but a little current from the flooding. The ship lifted off of

the blocks and surged north about 12 feet before the aft spring line stopped the

forward motion. The Shipwright supervisors quickly got control of the ship and

the undocking resumed with any further incident.

Was the surging of the ship due to the energy stored in the blocks, that I was

told about? Maybe! I never tested the theory. I always removed any slack in any

line before flooding a dock to undock a ship.

![]()

June 22, 2020

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

OSHA AND PAY RAISES

Congress and the Labor Department created OSHA and made most Shipwrights and

woodcraftsmen the highest paid WG-10 journeymen in the Shipyard. OSHA decided

that anyone working above a certain height must wear a safety harness, because

that work was considered hazardous. OSHA also found that anyone

installing/removing fiber glass insulation must wear a dust mask, because the

material was a health hazard.

Shipwrights and Woodcraftsmen, had for many years asked for extra compensation

for their exposure to the dangers now cited by OSHA. They were elated when the

Shipyard agreed, and they started receiving the extra pay.

The new OSHA rules also changed the way mast staging was erected or removed. The

requirement of wearing safety belts aloft made working from a tray held by a

crane, the only possible means for securing the safety belts to a strong, secure

place- the crane's hook. Shipwrights became airborne in trays -

erecting/removing staging. They also were considered working aloft when in a

high reach mobile equipment.

The man-day rate for 64 shop must have been the highest in the Shipyard.

![]()

June 21, 2020

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

A PARTING SHOT

The 9 inch (circumference) braided lines used to control a ship entering/leaving

a dock were always viewed by me as an accident about to happen. They would

stretch, not visibly, to the point of failure.

I only saw one fail. It was during the docking of Lexington in dry dock 4. The

line parted, with both end whipping across the dock. One hit the rigger's cart

used to move the lines, and destroyed it. The other missed a Foreman Rigger and

ship's force.

Never stand in the bight of a line, is an old sailor's warning. Sometimes it

can't be avoided. The parted line proved that a ship afloat, uncontrolled, is a

force that is hard to arrest. The Lexington flew off center, shearing two bilge

blocks from their moorings. The remaining breasting lines prevented the ship

from hitting the dock wall.

Most of the sheared bilge blocks floated to the surface. Calculations proved

that only two bilge blocks were displaced. The parted line was replaced and the

docking continued without incident.

Bill Domzalski later told me that the braided lines were replaced with kevlar

lines one third the size

June 21, 2020

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

THE NOBLE AND FAITHFUL DOG

Probably anyone, other than a Shipwright, would think upon seeing a Shipwright

dog - that it was a crude implement. In reality, it plays an important part

during the docking of a ship. The lumber components of a dock set up are secured

with dogs. A ship being centered over the docking blocks is always in motion -

usually in two directions. The braided lines used to control the ship are

elastic, and stretch under tension, allowing the ship to surge as the dock is

pumped dry. The ship is still in motion as it lands on the blocks. A ship

afloat, whether a destroyer or carrier, is a tremendous force that must be

controlled until it is firmly grounded. The dogs are the only things that keep

everything in place at the time of contact.

I have been contacted by email from former 64 shop employees, and reminded that

I didn't explain the labor extensive job it was in placing, and driving up those

dogs with a 8 pound maul. They are right, it was a lot of work. Like all

shipwrights, I was on the end of one of those mauls, driving up those dogs and

wondering when the Foreman would be satisfied with the number of dogs in place.

Always room for one more, would be his answer.

There are about 500 blocks in a slep carrier setup requiring about 12,000 dogs -

each one placed and driven up.

![]()

June 20, 2020

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

PHYSICS AND US

Sir Isaac Newton's law of gravity - a body in motion tends to stay in motion- a

body at rest tends to stay at rest describe the opposing forces used by 72 shop

Riggers to ease a Slep carrier into dock, while under constant control. The

carrier, with lines to power capstans fore and aft, moves into dock slowly. The

capstans at the head of the dock are straining to move the ship forward. The

capstans at near the caisson are straining to slow the forward motion.

Breasting lines - port and stbd - are straining to keep the ship centered in the

dock and slow it's forward motion. The resulting forces allow the ship to inch

forward, with the tightly coordinated movement of the breasting lines moving

forward, one ballard at a time to the next, while the rest wait for their turn

to move, one at a time.

In reflection, we have watched this control of a massive force of 40,000 tons of

a water borne object without appreciating the efforts of the riggers involved,

and the forces they had to control. It usually took about an hour for this tug

of war of opposing forces to move the ship into position.

A Bravo Zulo to those riggers and shipwrights, who with a calm resolve, made

those dockings seem routine.

![]()

June 15, 2020

Name: RICHARD BEGGS

E-mail: RICH.BEGGS@VERIZON.NET

Shop: 064

MAYBE - MAYBE

Maybe an extra-terrestrial archaeologist, sometime in the far future, will

discover a slag hammer in the debris left behind by 26 shop welders at the Navy

Yard in Philadelphia. Maybe he will determine, through this discovery, that

humans had the ability to fashion tools. Maybe he will never decide what the

tool was used for. Maybe he decided it's unique design, and probable use had an

important function in the advancement of civilization on this planet. And then,

maybe not.

![]()

June 12, 2020

Name: Tom queenan

E-mail: Tmquee@verizon.net

Shop: 26/2321

Bob Corsini,

I was just trying to elevate our lowly slag hammer to its proper place in

shipyard history.

I did not want 64 shop "dry dock dogs" get all the credit. Read the posts before

that and a picture of "dogs" was posted with a story attached. Just thought it

would be fun to point out the mundane and see if anyone would take the bait.

Hey its the shipyard, and what would it be if not for a little ball busting.

![]()

June 11, 2020

Name: Bob Corsini

E-mail: bobcorsini@gmail.com

Shop: 26

Howdy... Just had to say Tom Queenan, the slag hammer story IS funny. Don't give

up the comedian job just yet!

![]()

May 27, 2020

Name: Richard Hoffner Sr

E-mail: pauscg@gmail.com

I'm an avid naval history collector and a USCG Reservist who used to train at

PNSY. I have been trying to find the name the graphic artist of The Beacon. I

think his last name was Kunsavich but I'm not sure of the spelling or first

name. Can anyone tell me his full name? Thanks

![]()

May 20, 2020

Name: dan elliott

E-mail: lollygag5@aol.com

Shop: 26 shop

WANT TO let everyone know that my brother Frank Elliott 17 shop passed away last

night may 19 2020.

![]()

May 17, 2020

Name: Lee Bidlack

E-mail: fordlightning@etex.net

Shop: 06

Just wanted to let y'all know my brother Gordon "Skip" Bidlack passed away May

8th. He was in 17 shop and then moved down the coast landing finally at Naval

Air in Fla. Cancer from Agent Orange claims another. Services pending until the

National cemetery opens in Jacksonville, Fla.

![]()

May 16, 2020

Name: Bruce Conte

E-mail: :

Shop: Many

I am sad to read about the passing of Pat Casey. We worked together in the

"wave-guide" section within 56 shop and years later in P&E. I was Pat's

apprentice (boy) as we worked together installing the SPS-49 radar wave-guide.

Pat and I were both originally from South Philly, and we were constantly going

back and forth (in jest) about our family's heritage. I reached out to Pat a few

years ago and we talked for hours about the old days in 56. He told me his wife

Eileen had passed away a few years earlier. Pat was a good man!! To Pat's family

I expressed my deepest condolences. RIP my friend. You are with Eileen again

watching over your two sons.

![]()

May 15, 2020

Name: Dennis borger

E-mail: Denthewoodworker@gmail.com

Shop: 56 shop

Just wanted to let everyone in 56 shop know that pat Casey passed away he was

living in florida

![]()

April 25, 2020

Name: Joe Rosenberg

Shop: 64 shop

Never made a comment before,but just recently Jim Manzy,Ernie Hertler,and now

the Turtle all gone. Very sad.

![]()

April 24, 2020

Name: Dennis J Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911

Thomas William Terifay A.K.A. The Turtle, of Shop 26, & lived in Bellmawr NJ;

formerly of South Philadelphia, passed away on Sunday, April 19, 2020. Age 85.

Tom was an employee of the Welding Shop 26 at the Philadelphia Navy Yard for 41

years. He was an Army veteran, and a graduate of Southeast Catholic High School,

class of 1952. He was a wonderful husband, father, pop-pop, brother, uncle and

friend. He was loved by many and will be greatly missed.

Beloved husband of Rosemarie (nee Kraus). Devoted father of Thomas, Michael,

Kathleen (Tom), and Annmarie (John). Loving pop-pop to Ashley Rose, John Blair,

and Megan Marie. He is also survived by his brother Andrew (Nancy), and numerous

nieces, nephews, and other family and friends. He was predeceased by his

brothers John (Jane), Robert (Nan), and sister Dorothy (Robert).

https://www.gardnerfuneralhome.com/obituary/380063/Thomas-Terifay/

![]()

April 23, 2020

Name: Joseph J Caden III

E-mail: egorianlaw@yahoo.com

Shop: code 274 Planning Dept Design Division #4

Left electric wireway group with layoff notice 08/12/94. GDEB General Dynamics

Electric Boat hired me as a Designer 08/16/94. Virginia class CATIA V 3 trained

and worked there until layoff in 2001. Taught CATIA classes part time and in the

summer 0f 98 cotaught two eight day classes in a row with Jessie? The learners

were from NNS Newport News Shipbuilding, VA. Their leader gave me his card and I

called 3 years later. Started there 05/01/01 and remain there until this day on

Ford Class. Been teaching as a TR3 Training Representative 3 since 2005. Now

63.5 years old between 2 to 6 years from retirement. Fully believe it was all do

to my tenure at PNSY from 05/25/80 to 08/16/94. They taught me the business and

the love of it carried me through. Shipchecks, working with engineers, planners,

and other designers was the highlight of my worklife. Drawing and modifying

drawings on boards and then was placed on Computervision in 1983. Intro to

computer you would not believe what they do with these tools today,

![]()

April 20, 2020

Name: Dennis borger

E-mail: Denthewoodworker@gmail.com

Shop: 56 shop

Just wanted to let everyone know that jery Wright pasted away last night April

20 jery worked in 38 shop and worked for the coast guard in cape May nj

![]()

April 11, 2020

Name: Jim Perkins

E-mail: jimbo09991@netzero.com

Shop: 56

I concur with what Pete said. Stay safe everyone.

March 30, 2020

Name: Peter Johnston

E-mail: twelthj@gmail.com

Shop: 56

I just want to say to my fellow Yardbirds to take care of yourselves and your

families during this horrible time the world is experiencing with this virus.

God Bless all of you

February 16, 2020

Name: george kepner 62435-051

E-mail: gek1986@yahoo.com

Shop: 051

regret to say Ernie Hertler pasted away last night about 7:03pm Feb15th 2020 .

![]()

February 15, 2020

Name: george kepner 62435-051

E-mail: gek1986@yahoo.com

Shop: 051

just wanted to let everyone know that Ernie Hertler has become very sick with

leukemia and has chosen to refuse any more life assisting measures. please send

prayers out for the Hertler family

![]()

January 9, 2020

Name: Bob Daley

E-mail: hogdale@hotmail.com

Shop: 51

Does anyone know anything about self proclaimed tough guy shop 51 foreman Bill

Adair ? AKA Rotten Ralph.

![]()

January 4, 2020

Julio,

I regret to inform you and other PNSY friends, John W. "Jack" Halpin, 51 Shop

passed away May 29,2018 in Treasure Island, Florida.

Jack was a 1953 graduate of Southeast Catholic High School. Survived by wife

Cass, siblings Tom, Mike Joe, Catherine, nieces, nephews and dogs, Maggie and

Kirby. Former employee of the Phila. Navy Yard and Navy veteran. Missed by all.

Rest in peace.

Be well Julio,

Al

![]()

December 24, 2019

Name: Tom Maiorano

E-mail: tmaiorano1@verizon.net

Shop: 38 Shop

Want to wish all of my 38 Shop and PNSY brothers and sisters a Merry Christmas

and a Happy New Year.

![]()

December 21, 2019

Name: Ron Miller

E-mail: ronfish2002@yahoo.com

Shop: 31 Shop

I know I told this story several years ago, but I think there is a rule that old

guys are allowed to tell the same story more than once. It was December 1994,

the last day before Christmas shutdown, and with the closing scheduled for

September of '95 we all knew it would be our last Christmas at the Yard. My 31

Shop friend and carpool mate Bob Purdy and I waited in the parking lot along

with a small group of quiet Yardbirds. The weather matched our mood - it was

cold, damp and gloomy. The shuttle rolled into sight. "Hey it's the oldies bus,"

someone said. Some of you may remember shuttle bus driver who kept a little boom

box on the dashboard tuned to WOGL. We shuffled onto the bus, grabbing the last

few seats. Everyone sitting in silence. On the radio came the voice of Gene

Autry singing the opening lines of Rudolph the Red Nosed Reindeer. Someone in

the rear started to sing along. A few chuckles. Then laughter. A few join in.

Then the whole bus starts belting it out, roaring the final line, "You'll go

down in historeee!" We exit the bus with backpats for the driver, smiles and

mutual Merry Christmas greetings all around.

It is my favorite Shipyard memory,

Greetings Yardbirds, wherever you are.

I wish you a Merry Christmas, and a Happy New Year!

December 18, 2019

Name: JACK BALKIR

E-mail: JBALKIR@GMAIL.COM

Shop: CODE 1200 / SHOP 51

I would like to wish happy and healthy Christmas holidays to all my yardbird

friends and their families. God bless!

![]()

December 17, 2019

Name: Dennis Kaiser

E-mail: Dennis_Kaiser@Outlook.com

Shop: Code 911/Prop Foundry

Timothy Maza PNSY Shop 11 Shipfitter

November 18, 1947 - December 15, 2019 (In Florida)

It is with a heavy heart I am passing on the sad news of Tim's (A.K.A. Tiny Tim)

passing. Tim was a PNSY Shipfitter, and Shipfitter Foreman, as well as a friend

to many of us Yardbirds. He was my teacher when I transferred to PNSY from NAEC

in 1974. He taught me a lot about building and repairing ships as well as how

the shipyard worked. I've stayed in touch with Tim through the years, we spoke

every other month or so. It was fun listening to the old stories of how we both

made our way in the shipyard. He was a good man and will be sorely missed. Rest

in Piece my friend.

![]()

December 14, 2019

Name: Dennis Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911/Prop Shop

To all the Philly ex-YardBirds, Good cheer, great hope and the best that the

season has to offer for you and your family as you celebrate this time of Year.

Merry Christmas!

![]()

November 11, 2019

Name: Jim Yunker

E-mail: yunkerjf@netzero.net

Shop: 67

To all my fellow Veterans who have served or are serving:

THANK YOU FOR YOUR SERVICE !!

![]()

October 15, 2019

Name: GEVANS

E-mail: GEVANS1054@VERIZON.NET

Shop: 26

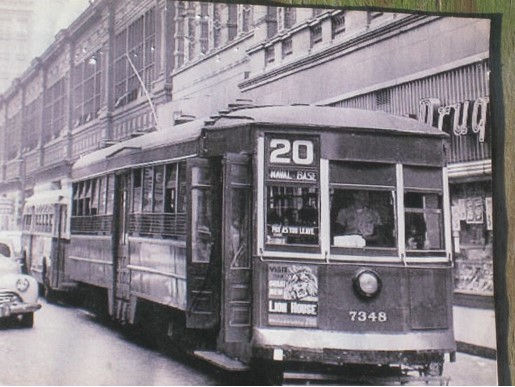

I believe to 20 Trolley was the longest line. It went from Chestnut Hill to the

Navy Yard. Down Germantown Ave., over US-1., down into the number street,

twisting through South Philly, coming out on 10th or 11th and Bigler, through

the City Dumps on to Packer Ave, behind the City Stadium, into the Navy Yard's

East Gate, behind the home on Broad St. to the Marine Barracks, on to Broad St.

in front of Marine Parade Grounds, to the terminal across from the Base's

Medical Bld.

![]()

October 14, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

Ron Miller: The route 15 trolley started in 1859 and stopped in 1992 when it was

changed to buses.

![]()

October 13, 2019

A picture for Ron Miller.

Richard Beggs (x64)

![]()

October 10, 2019

Name: Ron Miller

E-mail: ronfish2002@yahoo.com

Shop: 31

Thank you, Richard Beggs, for posting the picture of that old trolley. I printed

a copy and sent it to my brother, a trolley/train aficionado. We can remember

riding that type trolley on the #15 route along Girard Avenue to visit my

grandmother in Fishtown back in the 1950's. As I recall there was a conductor

sitting next to the middle doors, and you paid him as you exited. My father, who

worked at the Yard during WWII, spoke of seeing long lines of empty trolleys

waitng at the end of each shift.Thanks again for that little piece of history.

![]()

October 9, 2019

Name: G EVANS

E-mail: GEVANS1054@VERIZON.NET

Shop: 26

I shall try. Thanks Rich.

![]()

October 8, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

GOALS

A notable and attainable milestone for a man who reaches 30 years of retirement

would be to reach the same term of retirement as that of his term of service.

Good luck Jerry Evans.

![]()

October 4, 2019

Name: G EVANS

E-mail: GEVANS1054@VERIZON.NET

Shop: 26 SHOP

Thank you PNSY, and this great country. September marked 30 years in retirement

from government service.

![]()

September 23, 2019

One way to get to the yard was by trolley car. The old number 20

trolley went down 12th street (I think) and around the old Municipal stadium,

and into the yard with one stop on Broad street - across from the yard

dispensary.

I took that trolley on the day I came into the yard for the apprenticeship test,

and later on the day I was hired. The number 20 trolley was my means of travel

to the yard for about a year, until the bus stop opened where the blind man's

café now stands, and the trolley was discontinued.

I can remember that old wooden trolley car creaking and wracking as the motorman

opened it up around the stadium.

Richard Beggs (x64)

![]()

August 1, 2019

Name: Tom Varley

E-mail: Yelrav1@yahoo.com

Shop: 38

There will be a celebration of life for Chuck Kessler on August 10th.The address

for the celebration is 408 S.Carol Blvd, Upper Darby Pa. @ 4:00 PM.

For more information please contact his sister : Naomi Bailey PH # 610-680-1957

![]()

July 29, 2019

Name: Raymond Freda

E-mail: frayray227@aol.com

Shop: 06 Electrical section A

Obit for Pat Meeink, from x41 shop.

MEEINK PATRICK M.

Age 72, of Secane, PA, passed away June 16, 2019. Grandfather of Shane P. and

Ashley T. Meeink; survived by his sisters, Nuna, Kitty, Ann, Agnes; also

survived by longtime friend, Kevin (Donna) Meikle. Beloved father of the late

Shane Patrick and Patrick S. Meeink.

Relatives and friends are invited to his Visitation Friday June 21, 2019, 1

P.M., O'LEARY FUNERAL HOME, 640 E. Spring-field Rd., Springfield, PA 19064, and

to his Funeral Services 2 P.M. in the Funeral Home. Int. private.

Donations can be made in his memory for Wounded Warrior Project, 7020 A.C.

Skinner Parkway, Suite 100, Jacksonville, FL 32256.

![]()

July 10, 2019

Name: Karl Schluth

E-mail: pizzasteak@verizon.net

Shop: 031

Does anyone have any pictures of my father William A. Schluth Jr. He graduated

his 51 shop apprentice ship in 1959. He then went on to a Supervisory Position

in the Propeller Shop. Any remembrances (good or bad) or photos would be

appreciated.

![]()

June 22, 2019

Name: george kepner

E-mail: gek1986@yahoo.com

Shop: shop 051

does anyone remember working with a group of ship builders from a shipyard in

Japan . they worked as a team !! I remember they wouldn't even that a break for

the bathroom or anything else unless they went together .

![]()

June 18, 2019

Name: John Stangler

E-mail: jcstangler@aol.com

Shop: 26

https://www.congofuneralhome.com/notices/Charles-CramerJr

![]()

June 1, 2019

Name: Smilie Christie

E-mail: smilie@christiebroshvac.com

Shop: 17, C/500, C/229

https://www.legacy.com/obituaries/name/james-lafferty-obituary?pid=180248616&view=guestbook&utm_source=MarketingCloud&utm_medium=email&utm_campaign=GBAnniversaryEmail_20190313&utm_content=AddtoGuestBook

![]()

June 1, 2019

Name: GEVANS

E-mail: gevans10542verizon.net

Shop: SHOP 26

ASBESTOS

I have lived with this insidious fiber most of my life. We rapped ourselves in

it. We used it to protect things. We used it to create Containments on ships and

in the docks. Every Wire Rooms had it in. In the Fire Rooms and Engine Rooms. It

still haunts me.

![]()

May 26, 2019

Name: GEVANS

E-mail: GEVANS1054@VERIZON.NET

Shop: 26

We do need Lawyers. They have used the first law of business, CREATE A CUSTOMER.

They are for Society and against it. They are against Big Business and for it.

They are against Insurance Companies and for them. They are for the Medical

Industry and against it. Even layers need layers. What has been created?

![]()

May 26, 2019

Name: GEVANS

E-mail: gevans1054@verizon.net

Shop: 26

IN MEMORIAL

Sargent Robert J. Evans, USMC, killed in action. September 17, 1951, Korea.

![]()

May 26, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

Re: Robert L. Hofbauer

Ray d: It would help if you knew what your father-in-law did at the yard. Trade?

![]()

May 24, 2019

From: Ray d

Good morning,

I'm trying to find out if there is a way to find out what building my father in

law worked in? His name is Robert L. Hofbauer. Any help would be appreciated.

Thanks,

![]()

May 23, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizion.net

Shop: 064

LAWYERS

Shakespeare once answered when asked "what would make a better world" - said

"kill all the lawyers."

Dan: I went through three depositions for friends just like you described. There

were 10 lawyers asking the questions. Two of the cases settled out of court. I

was a witness at the other case in court. The same lawyers asked the same

questions, hoping for different answers. My friend won his case. I don't know

what the result was.

![]()

May 22, 2019

Name: Danny O'Kane

E-mail: dannyboydpo@rcn.com

Shop: 11 Shop

Rich ,

LAWYERS and WHORES

Couple of years ago I was asked by the family of a ship fitter I worked with

back in the 60's to testify about the conditions of asbestos at the yard during

that time period . He died from asbestosis related disease . He never smoked and

was the nicest guy you would ever meet .

I had to go into the lawyer's office that was representing his family and was

prepped for the deposition that I was to give on his behalf .At the deposition

his lawyer was not allowed to talk to me during the hearing . I was on my own to

face 12 lawyers representing the companies involved in the lawsuit . One by one

they came at me from across the table with all kinds of double talk . Every

chance I got I called for a break . This went on for two days.

I shut down each and every one of them and it felt good to put these wolves in

their places . They had no clue of the conditions we were working under at the

yard in the 60's .

Ask me if I would do it again ?? No way in hell!!

Oh yeah , the family won the trial and settled for quite a few dollars . They

deserved it .

![]()

May 22, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

LAWYERS

Jerry: You may not trust them, but there are times when you need them. Ever file

an asbestos law suit?

![]()

May 22, 2019

Name: GEVANS

E-mail: GEVANS1054@VERIZON.NET

Shop: SHOP 26

ASBESTOS COMMERICALS

They make it sound like it easy going. Remember never trust Lawyers and Car

Salesmen.

![]()

May 19, 2019

Name: Cliff Nash

E-mail: pnsycliff@aol.com

Shop: 06

Charles R. Rowan

Philadelphia, Pennsylvania

Jul 3, 1937 - May 16, 2019 (Age 81)

Murphy-Ruffenach Funeral Home Obituary

Charles was born on July 3, 1937 and passed away on Thursday, May 16, 2019.

Charles was a resident of New Jersey at the time of passing. Charles was a

United States Army Veteran and a retiree of the Philadelphia Naval Shipyard.

Relatives, friends, members of Quaker City and Gloucester City String Bands,

employees of the Philadelphia Phillies and members of the American Legion Post

135 are invited to his Visitation Tues. Another Viewing will be held Wed.

morning 10-11 AM at Old Zion Church, 628 N. Broad St., Phila., PA 19130. Funeral

Service 11 AM. Burial Fernwood Cem. Donations in his memory may be made to

either the above-mentioned Church, or Alex's Lemonade Stand, 1820 Williamstown

Rd., Franklinville, NJ 08322.

![]()

May 19, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

ASBESTOS COMMORCIALS

All navy ships built before 1980 were loaded with over 300 asbestos products.

Individual law suits were filed by many shipyard workers. The lawyers got a 30%

or 40% share of the settlement. Many workers had asbestos fibers in their lungs

without knowing it. A ticking time bomb waiting to go off 30 or 40 years later.

![]()

May 18, 2019

Name: Ron Miller

E-mail: ronfish2002@yahoo.com

Shop: 31

THOSE MESOTHELIOMA COMMERCIALS

I'm sure I'm not the only Yardbird who cringes when I hear them. Probably

exposed to asbestos, knowingly and unknowingly, numerous times. I know my first

time, for sure. In the fall of 1982, two weeks into the 31 Shop apprentice

training, I was learning engine lathe basics with my partner, Paul Muller, when

one of our instructors, Ed Fazekas, grabbed us to go on a "scavenger hunt" on

the Shangri-La, docked right outside of 31 Shop in the shadow of the Hammerhead.

The old carrier (interesting history, especially the name, see Wikepedia or

Google) was being readied for scrapping, and Fazekas wanted to scarf up any

machine tooling we could find for use in the apprentice section. We wandered all

over the ship for about half an hour, at one point ducking under some heavy duty

plastic curtains into a compartment where we were greeted by a Navy officer in a

full white "moon suit" and respirator. He told us in no uncertain terms to get

off the ship because it was undergoing asbestos removal. We retreated, but

Fazekas, undaunted, led us down another deck, and finally found the ship's

machine shop, which had been stripped of anything of use. I didn't think much of

it at the time, didn't really know what asbestos was, or its danger. I'm sure

those old conventional carriers in for SLEP were all loaded with it. I know

there was a huge class action settlement, and judging by the number of TV ads by

the lawyers, they must be getting a pretty good chunk of it. Well, I'm still

vertical, thankfully. I hope we all live to a hundred and pass away in our

sleep.

![]()

May 14, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

NAM VETS

Dan: We had about 6 apprentices leave for the Nam War, besides the Boxer. None

returned to the yard. Their names aren't on the wall. They must have returned

save.

May 13, 2019

Name: Danny O'Kane

E-mail: dannyboydpo@rcn.com

Shop: 11 Shop

MISSING BOXER

Rich , We lost TOO many of our generation in Nam .

Sorry to hear about your fellow worker. God bless his soul .

Danny .

USN '67-71'

![]()

May 13, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

A TIGER FOUND

I Found my missing boxer. He never got into the ring. He was KIA Viet Nam.

![]()

May 12, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

TAMONG A TIGER

I was recently out of my apprenticeship and joined the operations in dry dock 4

- building the Pratt and Dahlgren. I worked on most of the processes of 64 shop

- blocking, shoring, etc.

The hulls were nearing completion when I was given the job of building an

inclined ramp under the sterns of the ships for the installation of the shafts.

It was the only ramp ever built for the purpose. Large dollies were used in

later shaft installations.

Each frame was a different height and the length of the diagonal braces had to

be calculated. There was a new apprentice assigned to the gang. He was in the

Golden Gloves finals maybe this made him over confident. He was aloof and didn't

assist much in the work.

I showed him how to calculated the length of the diagonal braces using a two

foot square. He quickly adapted to his new job. and the square never left his

hands.

Everybody relaxed, including our future boxer. He transferred to another area

when the DLG's were ready to leave the dock. I lost touch with him and I don't

think he ever completed his apprenticeship. His destiny may have been the boxing

ring, or maybe his fate waited for him in Viet Nam.

![]()

May 12, 2019

Name: Mike Dougherty

E-mail: mikedougherty63@yahoo.com

Shop: 56 Shop

As an apprentice, one of my first jobs was replacing bolts and nuts on USS New

Jersey's fire main. They were steel and we used a chipping hammer on the tough

ones. I never passed a hearing test again bit I did use ear plugs after that.

I was one of the pier D elite who never wanted to work out front on surface

ships again. I even gat to go on a river run. I was in the overhead rack in the

aft torpedo room when we did the crashback dive. I never knew machinery could

scream.

Loaned out to the laggers I did finish work on the Blue Ridge. The boss

canvassed for the weekend and I said sure. We were marched Saturday morning to

pier 5 To a destroyers aft fire room where a bad fire had occurred. For 2 days

we removed lagging with wire cutters and hammers.The General Foreman stationed

himself at the ladder to inspire us I suppose.

Soon I would graduate to journeyman, get Riffed and lose my deferment. Salem

Nuclear power plant paid better and Atlantic City local 121 needed us bad They

also treated us bad but I still was very fortunate. Anybody else still alive?

![]()

May 12, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

ITS WHO YOU KNOW

Consistency of policy was admired by most and despised by some. It was the

policy of 64 shop, the Service Group and the Shipyard to not provide light duty

jobs to employees disabled due to non occupational injuries.

There were long term employees, in this situation, who were denied light duty

jobs during their term of disability. There were occasions, however when an

employee with a non occupational injury was placed in a light duty job. A close

relationship with the decision maker seemed to be the basis of the aberration.

The employee and the decision maker shared the same process of preventing the

over population of certain animals, as well as other things. The injured

employee was placed in a light duty job. He had a noticeable limp for some

years.

A tiger team was being selected for some project, and the light duty employee

volunteered. His limp was gone. The selection for the tiger team was a General

Foreman. He did not select the light duty employee whose limp returned after his

non selection. His light duty job continued, like many others, until he retired.

One strange light duty assignment was given to a otherwise healthy young man. He

had received hair transplants to his receding hair line. His head was swollen

due to the procedure and he couldn't wear a hard hat. He got a job in shop

planning until the swelling decreased. At least, he returned to duty.

![]()

May 11, 2019

Name: Richard Beggs

E-mail: rich.beggs @verizon.net

Shop: 064

OIL STAINS AND DISRESPECT

In 1967 the New Jersey was being overhauled to bring it back into commission.

The biggest job 64 shop had was the repair, recaulking and sanding of the teak

decks.

Careful attention was paid to prevent any oil spills on the deck. The dryed out

teak would absorb the oil like a sponge. A potato chip would leave a stain that

could not be removed.

We were successful during the long period of repairing, recaulking and sanding

of the decks. 56 shop landed some kind of a test stand Fwd on the Stbd side. We

saw too late that it had an internal oil leak. a large oil stain of about 100

square feet developed. We could not remove the stain. We were probably too

sensitive. The ship's force didn't notice it, or complain about it.

I attended the undocking conference held in the ship's wardroom. The docking

officer started the meeting with a bizarre statement. He said " lets get ready

to get this old bitch out of the dock before she falls apart." Two full

commanders, prospective ship's force were startled, but didn't say anything.

There was a different docking officer present on the day of the undocking. We

never saw the former docking officer again.

![]()

May 11, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

FAIL SAFE

Around 1970 64 shop decided to purchase Motorola transceiver radios for use in

the docking operations. The Radio Shack radios we were using were not

performing. They seemed to fail at critical times.

The new radios cost over $600 apiece. They came with a large charging station. A

great deal of thought went into deciding where to safely and securely keep them.

Someone found a large steel safe in the salvage yard. It was brought to Bldg

177. The combination for the safe was provided. The General Foreman wrote it on

a card and put it in his desk.

Everything went well until the day we needed the radios. The General Foreman

tried to open the safe. He tried the combination three times, and failed each

time. He went to his desk to recheck the combination he had recorded and stowed

there. He couldn't find the card he had recorded the combination on.

We had to use the Radio Shack radios once again, while a lock smith from 07 shop

was called to open the safe. He got the safe open. He disabled the combination,

as the shop requested. A hasp and keeper and a $2 lock was used to secure the

safe.

The key to the new lock was kept by the Superintendent in a key safe in his

office.

The purchase of additional radios and their chargers outsized the safe. A shelf

was added to a wall to provide space for all the radios and chargers - without

any security. They sat there unmolested until the fire that ended the existence

and history of Bldg 177.

![]()

May 10, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 64

WHAT CRISIS?

I was working in dry dock 4 on the LPH construction. The battles ships

California and Tennessee were in dry dock 5. B-52.s were landing at Philadelphia

International airport. They were being moved from Florida and other southern

states. it was 1962 - the Cuban Missile Crisis.

Kennedy and Khrushchev were playing hardball about Russian missiles in Cuba and

US missile in turkey. WW-3 could start. Work at the yard continued. Most workers

seemed oblivious to what was happening. The biggest question for most was "how

does it look for the weekend?" I don't think Danny boy was aboard then.

![]()

May 9, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

ALL HANDS ON DECK

Strange things seem to happen to me while I worked at pier D. I was in a tank

with two shipwrights in a sub on the rail as they took circularity readings of

the hull. It was about 1430. The General stuck his head into the tank, and told

us to report to dry dock 4 at once. In an unprecedent action, the shop

Superintendent ordered every person in 64 shop to report to dry dock 4 ASAP.

We thought the worst. WW-3 had started, we had gone to dev-con 1, the barbarians

were at the gates, battle stations, dive -dive. We arrived at the dock. There

was a LST wet berthed there. The shop Superintendent stood on the brow. Once

aboard, you did not get off.

The ship was due to depart the shipyard when it discovered that it's work

package included the blasting and painting of the superstructure and mast. They

didn't want it now, they wanted it RIGHT NOW,

Every cable run, light globe, port hole, fan room vent had to be covered,

including cables and lights on the mast. There were about 150 people available.

Every man woman and child (they were part of co-op program from the city) were

expected to report to the ship. Some were delayed gathering material. The

whistle at 1600 stopped about half. Car pool obligations stopped more. About 50

people showed up. Children were excused.

The entire second shift (12 men and a Foreman) showed up. Work begun, and like

all jobs, it got done without any fatalities. It was the first time our

superintendent pulled a 16 hour shift.

Painting began the following day. All the cars parked in 88 area got a dusting

of hazed gray paint. The ship left looking great. The shop Superintendent,

however, was not pleased with the number of people who answered his urgent call

to duty. Next time, he vowed to take names of malingers. and have them

disciplined, as appropriate.

![]()

May 9, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

THE MORE THINGS CHANGE - ETC

I had mentioned in an earlier post that I didn't exert much influence in the

process and methods of the shop at pier D. I did try on one occasion. The sail

staging was constructed of 4x8 timber legs and 2x12 headers - a large bulky

timber frame staging. The 4x8x 32 feet were not readily available. The legs we

had were used since I was an apprentice, 20 years ago. They were warped, twisted

and full of holes. I scrapped them. New 4x8x 32 feet legs were ordered.

The sail waited to be staged. I decided to use pipe staging, which was the

method used by Portsmouth Naval Shipyard to stage their sub's sails.

Our General Foreman was not around when I started to build the sail staging with

pipe. He only seen it when we were done. There was nothing he could do, but

accept it - however reluctantly. The pipe staging worked better, being easier to

adjust for the installation of masts and scopes. I submitted a benny sugg and

the General Foreman rejected it. I appealed and the suggestion was approved.

It was used on one sub, and never again. I was temporarily transferred to one of

the DLG's for it's tile installation. During my absence the 4x4x32 feet legs

arrived. When I returned to pier D, the shipwrights were once again building the

timber frame staging for the sail of a newly arrive sub. One shipwright

whispered to me that my pipe staging idea was the reason I was transferred. He

may have been right.

The early out program of 1972 created openings for General Foreman in 64 shop,

since every General Foreman left. I was one of the Foreman promoted.

Pier D was still there. The Belknap was berthed in the back channel, and there

were a few shipwrights on board laying out lines for the new deck houses. I went

back a few times to advise them. The Belknap moved to dry dock 4. Pier D was

slated to be demolished, along with piers A, B and C. There would be a big empty

space where the piers once stood, sometimes with subs at each of them. The saga

of pier D and it cast of characters is forgotten now, may be it's for the best.

![]()

May 9, 2019

Name: GEVANS

E-mail: GEVANS1054@VERIZON.NET

Shop: SHOP 26

LCC-19 PART II

Supply Dept. hired 3 former Welder Supervisors to jump start the Structural

Material Control Ctr. (MCC). New construction hulls completed, time for

outfitting. Most of 11, 26, 41's taken care of time for 17 Shop to take care of

creatures that will live on the ships. LCC_19 loomed up.

Many compartments changer, up grades, equipment changes, made it difficult to

keep track of the needs in each space on the ship.

Our first job was straighten up the back of 990 bldg. Material for all the new

construction plus shop stores was in and out the bldg. The Supply IG was due on

Monday. We were told to fix up the area. We innovated and moved all material to

steel field and the submarine lay down. Monday morning Big Meeting. The

Supervisor Shop Planner 17 Shop accused us o stealing the material and selling

it outside the shipyard.

![]()

May 9, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

LABOR/MANAGEMENT RELATONS AT PIER D MOVES INTO THE 19TH CENTURY

Overtime at pier D for shipwrights was scarce to nom-existing. There were a few

operations that shipwrights were called to assist 38 shop. The installation of

the snorkel mast required two 4x4 shores secured to the mast - to prevent it

from lowering after the crane released it. 38 shop usually requested two

shipwrights to install the shores on the day the snorkel mast was installed. The

operation took about an hour. The two shipwrights spent the rest of the day

standing by.

Overtime was being closely watched. 38 shop asked our General Foreman if we

would supply the shores, and they would install them - sans shipwrights. The

General Foreman agreed.

The shipwrights were beyond upset on Monday morning when they discovered the

snorkel mast had been installed without their help. They asked to see the

General Foreman. I advised against it. A low profile, I cautioned was necessary

to survive at pier D. They insisted to see the General Foreman.

They were last seen loading their tool boxes on the shop truck - to begin their

exile to the dreaded river front.

![]()

May 9, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

Bill Ennis helped us write supporting letters for Outstanding Performance

ratings. Without his help we would never get those letters past IRO.

![]()

May 8, 2019

Name: Dennis Kaiser

E-mail: dennis_kaiser@outlook.com

Shop: Code 911

Bill ENNIS May 6, 2019.

Former PNSY Shipwright, Engineering Tech, NAVSHIPSO, retired Defense Dept.

employee and Army Veteran. Relatives, friends, members of American Legion Post

810, Knights of Columbus Council #1284, and Elks Lodge #585 Wildwood, and Order

of the Moose are invited to his Viewing Friday evening, 5/10/2019, 7 - 9 P.M. at

BURNS FUNERAL HOME, 9708 Frankford Ave., Phila., PA 19114. A second Viewing will

be held Saturday morning at St. Matthew Church, 3000 Cottman Ave., Phila., PA

19149. Funeral Mass 10:30 A.M. In lieu of flowers, donations in his memory to

JDRF, 26 Broadway, 14th Floor, New York, NY 10004.

![]()

May 8, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

SCHEMERS AND DREAMERS

Men with advanced skills were usually given jobs requiring that skill set. They

and only they, were repeatedly assigned to these tasks. It had been that way

before, and during the years I worked out front, as a Foreman, away from the fun

house at pier D.

Some of these shipwrights would, if they could influence the schedule of

completion of these tasks - so that overtime was necessary.

I had worked every one of these operations as an apprentice and journeyman while

at pier D before these shipwrights were now on the scene. It was a strategic

battle at times by opposing forces. One side - me and the other side the alleged

specialist shipwright.

One side preparing and eliminating any cause that would delay the process, and

the other side trying to prevent the ease of process, with overtime being their

objective.

I won some, and probably lost more. But it introduced a new dynamic into the

process at pier D. I was transferred back out front after a few years when the

DLG overhaul program started, and things got back to abnormal at pier D.

![]()

May 8, 2019

Name: Richard Beggs

E-mail: rich.beggs@verizon.net

Shop: 064

PIER D - A MALAISE

As previously noted, pier D was a strange place to work. The men working there

seemed privileged to be there, and feared being transferred. It may have been

the attitude of men during the great depression who subjugated themselves to

hold a job, any job.

Watching the three shipwrights, who didn't seem to have a Foreman directing

their clandestine activities , wander around while every one else was working,

would have resulted in turmoil in any other 64 shop work site.

They often filled an overtime billet, continuing to search for things not yet

lost. I don't think they ever tried to perform any shipwright related tasks.

I never worked overtime at pier D. it was rare for an apprentice to do so, and

my attitude didn't help. I had repeatedly asked for a transfer. The supervisors

may have thought I was trying to trick them like Br'er rabbit from Aesop's

fables. They wouldn't transfer me.